|

Value Stream Mapping is a specific method for documenting, analyzing, and optimizing the flow of information or materials to produce a product or service. The primary objective of VSM is to eliminate waste and streamline complex processes to increase efficiency. This technique provides companies with a visual roadmap of steps to identify bottlenecks in the value stream and optimize workflow. A value stream is a set of actions that enables a company to identify areas of value that can enhance the product or service offered to the customer. The goal of a value stream is to eliminate waste and identify bottlenecks to improve the overall efficiency of a process or service. VSM as part of Enterprise ArchitectureValue Stream Mapping is a key technique used in the Business Architecture phase of the Enterprise Architecture (EA) framework. This phase focuses on creating a comprehensive understanding of the organization's business processes and capabilities, and how they support the overall business strategy. VSM is used to map the flow of materials, information, and work through the organization's value streams, helping to identify inefficiencies and opportunities for improvement. As part of the Business Architecture phase, VSM is typically used to achieve the following objectives:

Overall, VSM is a valuable tool for organizations looking to optimize their business processes and improve their overall performance. By using VSM as part of the Business Architecture phase of the EA framework, organizations can gain a comprehensive understanding of their value streams and develop a roadmap for continuous improvement. Benefits of VSM

Challenges of VSM

In summary, VSM is a powerful tool for identifying waste, improving process flow, and increasing transparency. However, it also has challenges, including the need for expertise, the time required to complete the process, and resistance to change. By addressing these challenges, organizations can effectively leverage VSM to achieve process improvements and drive business results. Step-by-Step Guide to VSMValue Stream Mapping involves a series of steps aimed at documenting, analyzing, and optimizing the flow of information or materials to produce a product or service. The process involves a cross-functional team working together to create a visual representation of the entire value stream, from start to finish. Here is a step by step guide to Value Stream Mapping:

By following these steps, organizations can effectively leverage VSM to achieve process improvements and drive business results. It is important to involve a cross-functional team and to use data to drive decision-making, while focusing on continuous improvement to ensure sustained success. What are the Outputs from a VSM?The outputs of a Value Stream Mapping exercise typically include the following artifacts:

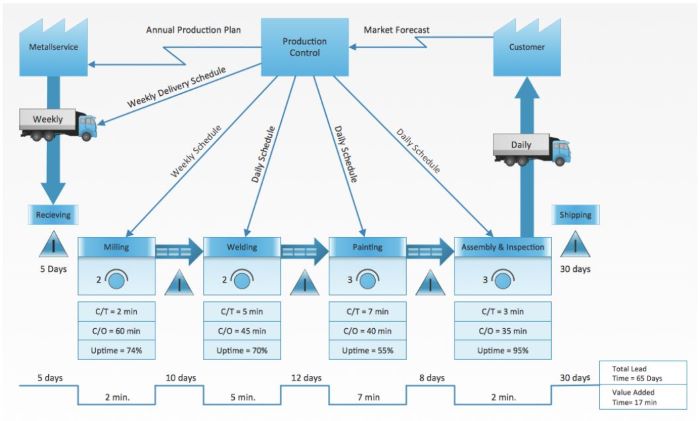

The figure below shows an example of a Value Stream Map. This will typically include a series of boxes or process steps, connected by arrows to show the flow of materials or information. The map may also include metrics such as lead time, cycle time, and processing time, to help identify areas for improvement. Additionally, Value Stream Maps may include data on inventory levels, batch sizes, and changeover times. Example Value Stream Map (Source Conceptdraw) By producing these artifacts, organizations can effectively leverage VSM to achieve process improvements and drive business results. It is important to involve a cross-functional team and to use data to drive decision-making, while focusing on continuous improvement to ensure sustained success. Examples of VSM in ActionHere are a few examples of companies that have successfully used Value Stream Mapping (VSM) to improve their processes and drive business results:

These are just a few examples of how companies have successfully used VSM to drive process improvements and achieve business results. By leveraging the insights gained through VSM, organizations can optimize their processes, reduce costs, and improve customer satisfaction. SummaryValue Stream Mapping is a powerful technique for improving business processes, reducing waste, and increasing efficiency. By mapping the flow of materials, information, and work through a value stream, organizations can identify bottlenecks, waste, and inefficiencies, and develop solutions to improve their processes. The benefits of VSM include reduced costs, increased efficiency, improved quality, and better customer satisfaction. However, there are also challenges to using VSM effectively, such as the need for cross-functional collaboration and the difficulty of quantifying the benefits of process improvements. To overcome these challenges, organizations should focus on involving all stakeholders in the process, using data to drive decision-making, and focusing on continuous improvement to ensure sustained success. Overall, VSM is a valuable tool for any organization looking to optimize their processes and improve their bottom line.

0 Comments

Leave a Reply. |

AuthorTim Hardwick is a Strategy & Transformation Consultant specialising in Technology Strategy & Enterprise Architecture Archives

March 2025

Categories

All

|